High quality cotton is the basic component in textile weaving.

Cotton is mainly imported from Italy but sometimes it can also be found domestically.

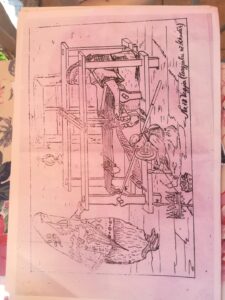

The loom weaving of fabric comprises a total of 6 processes applied with craftsmanship.

First, the cotton yarn is wound on spools. These spools are inserted on a rack known as a creel.

The first process is winding and warping. During this phase, each yarn must be taken and interlaced in a certain manner.

After winding and warping, the shedding process follows. This process is performed by two people – one wrapping the yarn into the warp beam, while the other letting it off/releasing it.

Once the shedding process is completed, the yarns are put onto the loom threaded through the eye of heddles frame which hang from the harness/shaft of the loom. The process is performed again by two people where one gives the yarn, while the other takes it. Each of the yarns also passes through the reed which is the fourth process. During this phase, the same yarns that have passed through the heddles, are twisted in two-ply patterns.

The processes of passing through the heddles frame and into the reed take about 3 hours to complete.

After passing through the reed, the yarns are interlaced and so the weaving process of the fabric into the loom starts.

Once the fabric is woven on the loom, the final process is embroidery. During this phase, embroidery starts on the front side of the fabric, fillings and patches are added; next, the needle is threaded in the same way onto the back side of the fabric to continue embroidery so that either side of the fabric matches appropriately.

Embroidery as a craft of decorating fabric or other materials, uses a needle to apply the yarn or thread and takes from 12 hours to 3 working days.

The designs are diversified and range from customized with human names to pets and other various items.

Colors come in a wide variety selected from ready to use thread palettes. Bright or even powerful colors cost more.

Powerful colors are: Red-datro, black-nero, orange-korn, creta, gray-monaco, grixho medio, green-prato, verde.

Traditionally applied dyeing:

Black color: To obtain the black color, the ash plant is taken in times of good weather (no raining). It is presoaked into a pot or pan with water 5-6 days before dyeing. On the dyeing day, the ash leaves are boiled and taken out. The thread is dipped into water, covered and left to cool down. The scoured thread is rinsed and pulled out to dry.

Verre/alder (light tan) color: To obtain this color, we use verre plant.

Red color: To obtain the red color, the paint is poured into a pot or pan of boiling water. The thread is dipped and left to boil for 5-6 minutes. The pan is removed from heat and left to cool down. The scoured thread is rinsed and pulled out to dry. The traditional dyeing of loom woven fabrics has not used many colors. Red has been used predominantly, and white as well; while the least used colors have been black, blue and green.